BS 1868 – Specification for steel check valves (flanged and butt-welding ends) for the petroleum, petrochemical and allied industries

BS 1868:1975+A1:1990 specifies requirements for cast or forged steel check valves with flanged orbutt-welding ends of the following types:

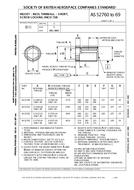

a) swing, for vertical or horizontal flow (see Figure 1);

b) lift:

i) piston type, for angle or horizontal flow (see Figure 2);

ii) ball type, for angle or horizontal flow (see Figure 3);

iii) ball type, for vertical flow (see Figure 4);

iv) disk type, for vertical flow (see Figure 5).

The terms “vertical”, “horizontal” and “angle” relate to the axes of the body ends.

When swing check valves are used in vertical lines the flow must be in an upward direction. For thepurposes of this standard any line with a slope (upward or downward) of 5 or less is deemed to behorizontal. In the case of angle pattern valves the inlet should be vertical.

Nominal sizes, ratings, design, materials, marking and shipping for swing, piston, ball and disk valves for Class 150 up to Class 2500 and of nominal sizes 15 to 600 mm. Appendix for application to piping systems with BS 4504:Part 1.

Cross References:

BS 1133-6

BS 1400

BS 1501-1506

BS 1503

BS 1560-2

BS 1600-2

BS 1832

BS 2080

BS 2872

BS 2874

BS 3071

BS 3076

BS 3351

BS 4504-1

BS 4882

BS 6755-1

Incorporates the following:

AMD 6563 published 31 July 1990

Amends and replaces BS 1868:1975. Corrigendum, January 2010

Product Details

- Published:

- 01/31/2010

- ISBN(s):

- 9780580703195

- Number of Pages:

- 28

- File Size:

- 1 file , 890 KB

- Product Code(s):

- 30215577, 30215577, 30215577

- Note:

- This product is unavailable in Ukraine, Russia, Belarus